In the field of CNC machine tool processing applications, the fusion application of China's machine tool loading and unloading robots and CNC machine tools has been at the forefront of development. From the perspective of industry application, there have also been major changes:

(1) Working island: single-pair single-competition plus single-to-many online processing.

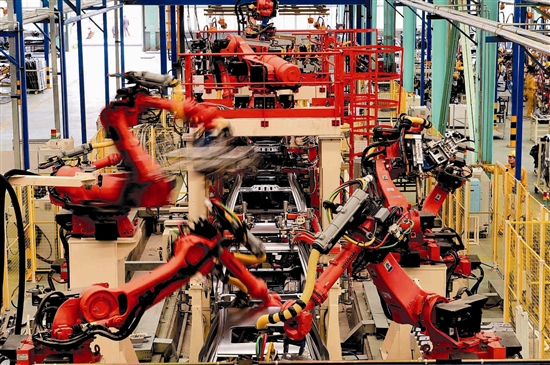

(2) Flexible Manufacturing System (FMS): Based on the network control of the flexible machine plus line, the PLC control platform is used to connect multiple robots, multiple CNC machine tools and their auxiliary equipment through the industrial Ethernet bus. The beat is performed in an orderly automatic production.

(3) Digital workshop: With CADCAMCAPPSMES auxiliary production tools, logistics technology and sensing technology, it has the functions of production process monitoring, online fault real-time feedback, processing technology data management, tool information management, equipment maintenance data management, product information recording, etc. Unmanned processing requirements, to achieve production planning, operational coordination and optimization of the processing system.

With the rise of labor costs, lack of skilled talents, high-risk environmental protection, and high-intensity operations, industrial robots have been widely recognized and used in production and have become the focus of social attention. The government is also taking this to promote industrial transformation and upgrading. Enterprises use it to carry out technological transformation, transform production methods and improve operational efficiency. However, China's robot possession is not large, national brands are still under cultivation, and comprehensive competitiveness needs to be improved. So, what kind of model will the robot industry move forward? At this stage, there is a need for the coordinated development of the robotic machine enterprise, the key component suppliers of robots, and the industrial chain of robot integrators.

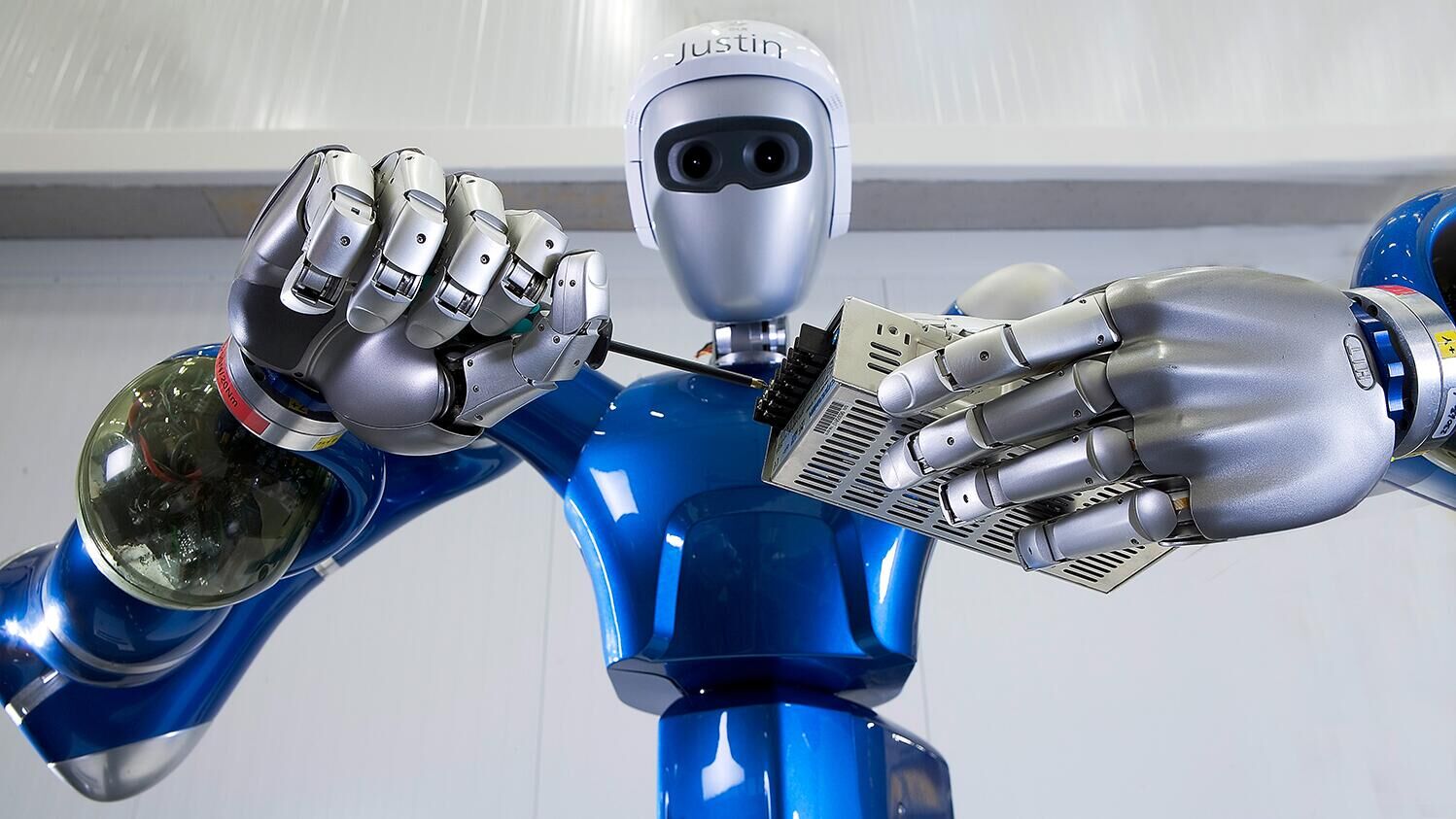

The robot participates in the machining and manufacturing of the machine tool parts to realize automation. The special machine tool serves the precision machining of the robot-specific reducer, improves the processing quality and mass production efficiency, etc., and has a great space for integration and development. With the strategic cooperation between the two companies, robot companies can achieve the following goals by means of the manufacturing and process technology capabilities of machine tool manufacturers:

(1) Robot-oriented body castings and reducer structural parts, jointly research and form batch precision manufacturing technology, improve the batch production capacity and process level of robots, overcome reliability and consistency technology, and achieve efficient, stable and precise beat production.

(2) Facing the integration ability of robot tooling, fixtures and machine production lines, and entrusting the promotion of application robots by means of the channel resources of the majority of end machine customers of major machine tool factories.

(3) Research and development of industrial robots for machine bed sheet machines and production line cutting and parts handling, scraping, chamfering, polishing, welding, spraying (powder) and other automation, flexible production, machine tool enterprises and industrial robot companies To realize the automatic processing of the whole machine parts and promote the technical level of machine tool manufacturing.

(4) The key components of the mechanical body of the industrial robot, such as the turntable, the boom, the box, the support sleeve, the arm, the wrist, etc., the dimensional accuracy and the shape tolerance are all required to be high, for the machining equipment, fixtures, The gauges and the like have high requirements; the structural optimization and processing of key components such as the cycloidal tooth housing, the planetary pin wheel, the eccentric shaft and the planet carrier of the robot reducer.

Echo