Different types of electromagnetic wide should be used for different work places. Solenoid valves such as refrigerant lines cannot be used in water lines because water can foul and inevitably have solid impurities, which can easily block small balance holes on the diaphragm. The electromagnetic valve used on the oil return pipe of the oil separator should have anti-vibration measures to prevent the fluctuation of the compressor discharge pressure from affecting the opening and closing of the auxiliary valve. Solenoid valves for suction pipes are required to be dew condensation, so use a moisture-proof coil or a closed solenoid valve. When the ambient temperature is higher than 40 °C, use a heat-proof coil or the like.

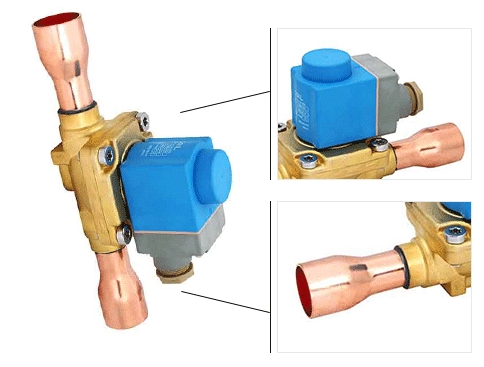

The solenoid valve must be coiled up and installed vertically in the pipeline. Otherwise, it will fail due to the core iron not working properly. The flow direction of the medium in the solenoid valve flows from the upper side of the valve core to the lower side, so it must be installed according to the direction of the arrow indicated on the valve body. The direction of the arrow is the flow direction of the medium in the pipeline.

In order to check whether the solenoid valve is working properly, a light bulb can be connected in parallel with the solenoid valve power line to indicate its switching condition. It is also possible to connect a manual switch in series with the solenoid valve power supply line. When the manual switch is used to turn the circuit on and off, if the sound of the spool in the solenoid valve can be heard, the operation of the solenoid valve is normal. The malfunction of the solenoid valve mainly occurs in the three aspects of coil burnout, valve core jam and core iron remanence. It can be inspected and confirmed by the above method. If the core iron remanence does not fall automatically after the power is cut off, the core iron can be taken out and removed by heating or beating.

Echo